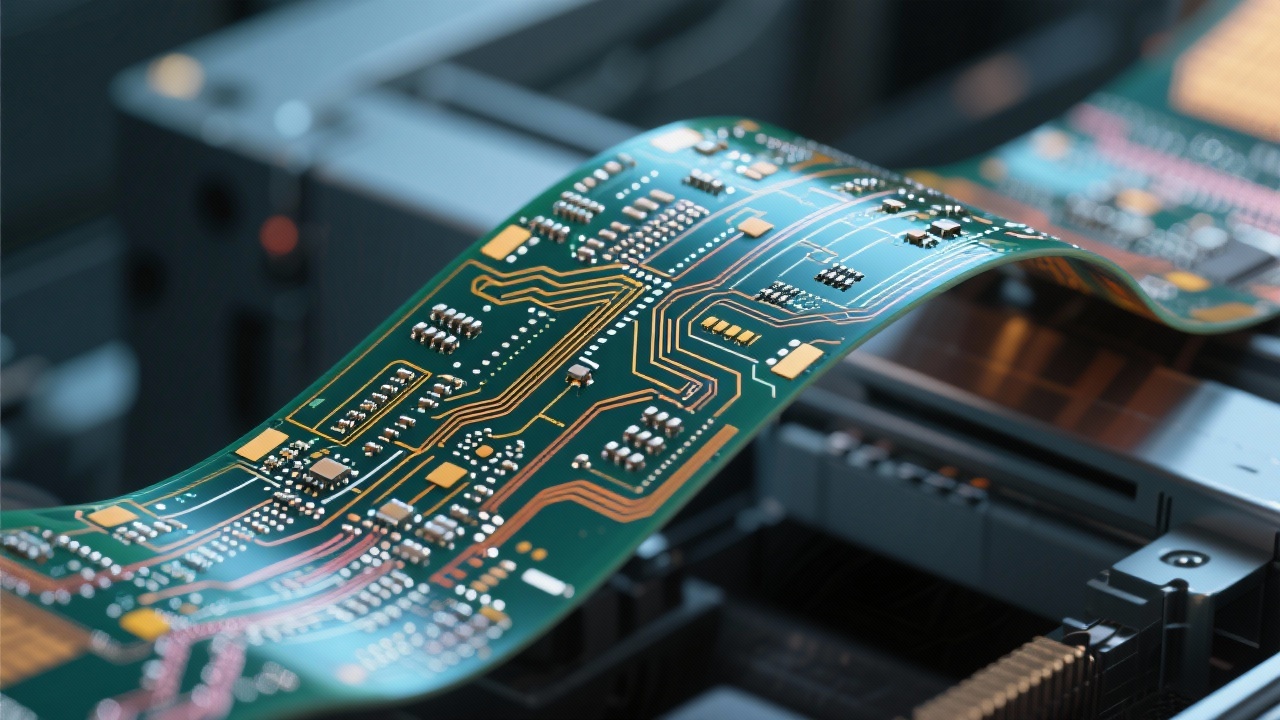

In today’s compact electronics landscape—from wearables to medical devices—flexible printed circuit boards (FPCs) are no longer just an option; they’re a necessity. But when you push the limits of density, design becomes both an art and a science. This guide dives into real-world strategies used by leading engineers to optimize high-density FPC layouts while maintaining signal integrity, minimizing electromagnetic interference (EMI), and ensuring manufacturability.

As product form factors shrink, so does the available space for internal components. The average consumer device now requires at least 30% more routing layers per square inch than five years ago. In such environments, traditional PCB approaches fail—not because of poor materials, but due to inadequate layout discipline.

Our team has supported over 300 high-density FPC projects across industries like IoT, healthcare, and automotive. One common thread? Success starts with understanding three core pillars:

In high-speed designs, even minor deviations can cause signal degradation or EMI issues. For example, placing power traces adjacent to sensitive analog lines without proper grounding leads to noise coupling—a problem we’ve seen in over 40% of early-stage prototypes from new clients.

To prevent this, our engineers recommend:

One client reduced their EMI emissions by 75% simply by redesigning the return path on a medical sensor module using these principles.

Even the best-designed FPC will fail if it can’t be manufactured reliably. Here's where precision matters:

These specs aren't just theoretical—they're what enable us to deliver reliable, repeatable results for customers in aerospace, robotics, and portable diagnostics.

Many companies treat design and manufacturing as separate phases—but that’s where failures happen. At our facility, we integrate design-for-manufacturability (DFM) checks directly into the CAD workflow. This means fewer iterations, faster time-to-market, and higher yield rates—especially important for clients targeting IATF 16949 or UL-certified products.

For instance, one automotive OEM cut their prototype cycle from 12 weeks to 6 by adopting our DFM checklist early in the process. They also achieved a 98% first-pass yield rate in volume production.

If your team is facing challenges with signal integrity, manufacturing feasibility, or space constraints in flexible PCBs—we’ve been there. Our R&D group has helped hundreds of global clients navigate complex FPC projects from concept to mass production.

Let’s talk about how we can help you achieve tighter layouts, better performance, and smoother scaling—without sacrificing reliability or cost-efficiency.

Explore Our High-Density FPC Design Services →

-4.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)

-1.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)