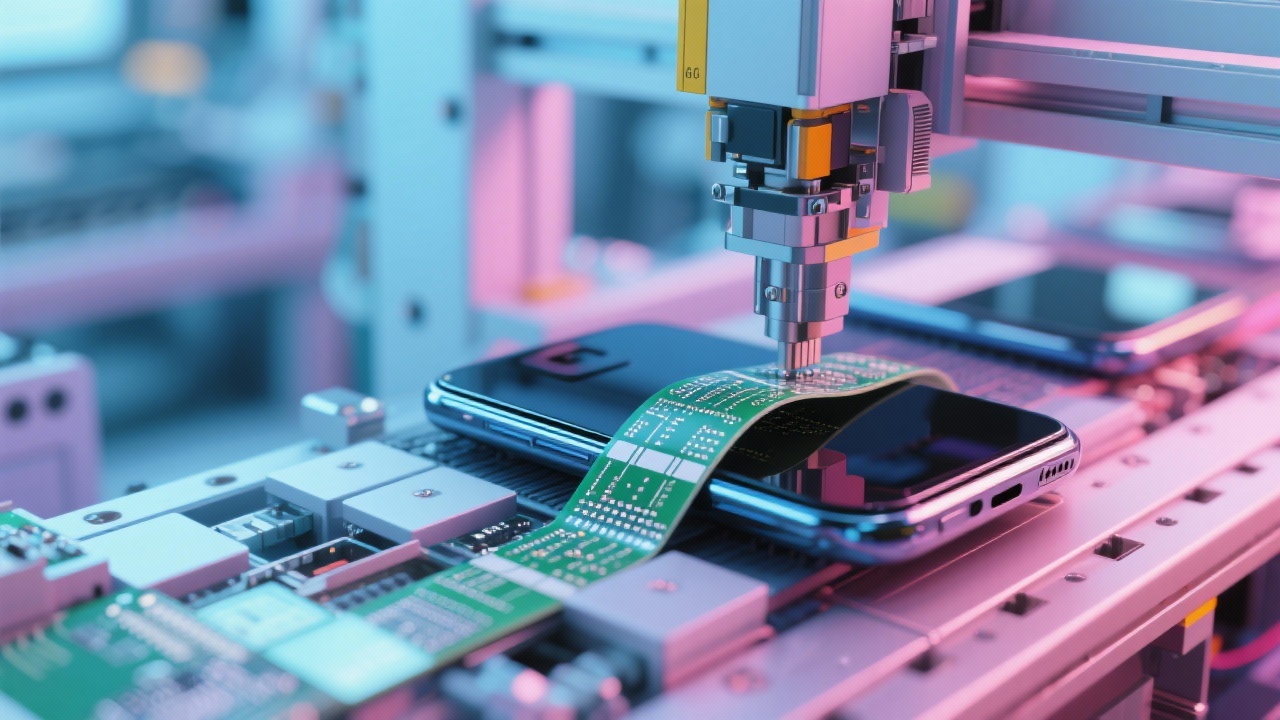

In today’s compact electronics—from wearables to medical devices—flexible printed circuits (FPCs) are pushing the limits of miniaturization. But with higher density comes greater complexity. The key to success? A systematic approach that balances design precision, manufacturability, and real-world performance.

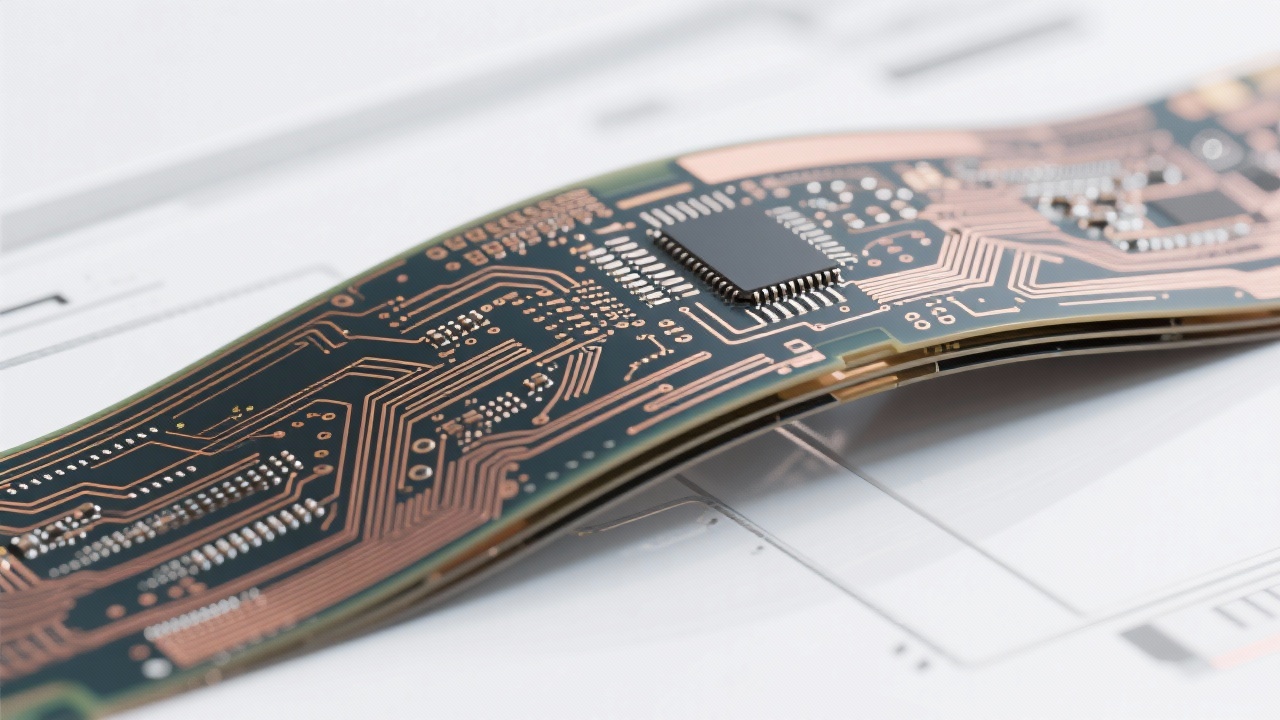

When space is at a premium, every millimeter counts. In high-density applications, designers often face trade-offs between signal routing efficiency and thermal management. For example, reducing trace spacing from 0.2mm to 0.1mm can increase component density by up to 40%, but it also demands tighter control over copper thickness, dielectric uniformity, and via placement. This isn’t just theoretical—it’s what we see in our clients’ projects daily.

Signal interference remains one of the top reasons for field failures in flexible PCBs. Our team has helped multiple OEMs reduce crosstalk by implementing ground plane shielding between critical signal layers and using staggered via patterns to minimize electromagnetic coupling. In one case, moving from a single-layer shield to a dual-layer isolation reduced EMI emissions by 62%—a result confirmed through lab testing using CISPR 11 standards.

What makes this possible? It starts with design rules that match manufacturing capabilities. At our facility, we consistently achieve 0.1mm line width and spacing, along with 0.2mm drill diameters—enabling complex multi-layer FPC designs that would otherwise be unfeasible.

FPCs aren't static—they move. Whether it's a smartphone hinge or a surgical tool, repeated flexing creates localized stress points. Without proper design, these areas fail prematurely. We’ve developed a proprietary method combining material selection (polyimide vs. liquid crystal polymer), controlled bend radius (minimum 3mm), and reinforced copper plating to extend fatigue life by over 3x compared to standard approaches.

Our engineers don’t just design—they validate. Using finite element analysis (FEA), we simulate thousands of flex cycles before prototyping. That way, you get a product that works not just on paper, but in the real world.

You may have encountered similar challenges: tight tolerances, signal noise, or unexpected failures during prototype testing. What worked for us might work for you too.

We've delivered high-density FPC solutions to leading brands in healthcare, consumer tech, and industrial automation. Let’s discuss how we can support your next project—from concept to production.

Explore Our High-Density FPC Design Services

-1.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)