In the era of rapid technological development, high - density flexible printed circuit boards (FPCs) have become a key component in various industries, especially in space - sensitive fields such as consumer electronics and medical devices. This article delves deep into the core technical difficulties in high - density FPC design and manufacturing process innovation.

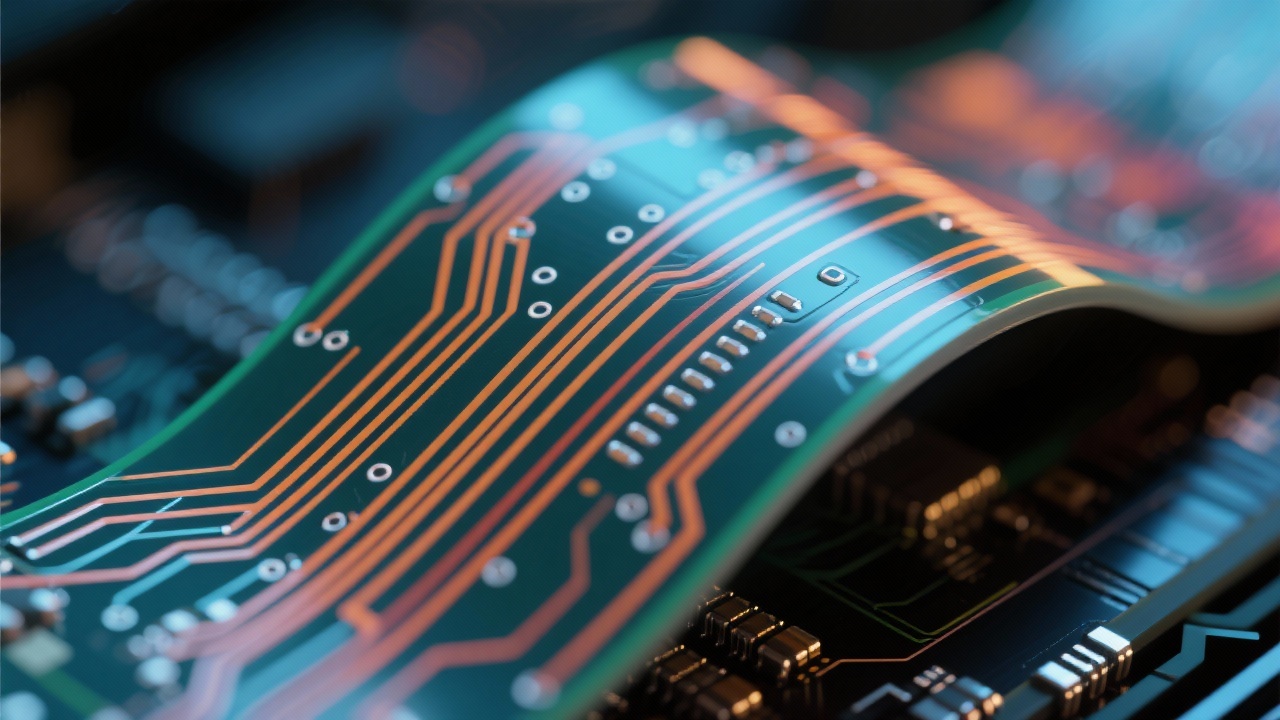

Layout optimization, trace spacing control, and via design are crucial aspects in high - density FPC design. For single - sided, double - sided, and multi - layer FPCs, designers face significant challenges in achieving the best layout. The minimum trace spacing is set at 0.1mm, which requires precise control during the design process. Via design also plays a vital role in ensuring signal integrity. For example, improper via design can lead to signal loss and electromagnetic interference.

In high - density FPC design, signal crosstalk and electromagnetic compatibility are major concerns. In space - sensitive applications like consumer electronics and medical devices, signal crosstalk can seriously affect the performance of the entire system. To address this issue, designers need to optimize the layout and use appropriate shielding techniques. By referring to real - world application cases in these industries, we can see how effective layout optimization can reduce signal crosstalk and improve electromagnetic compatibility.

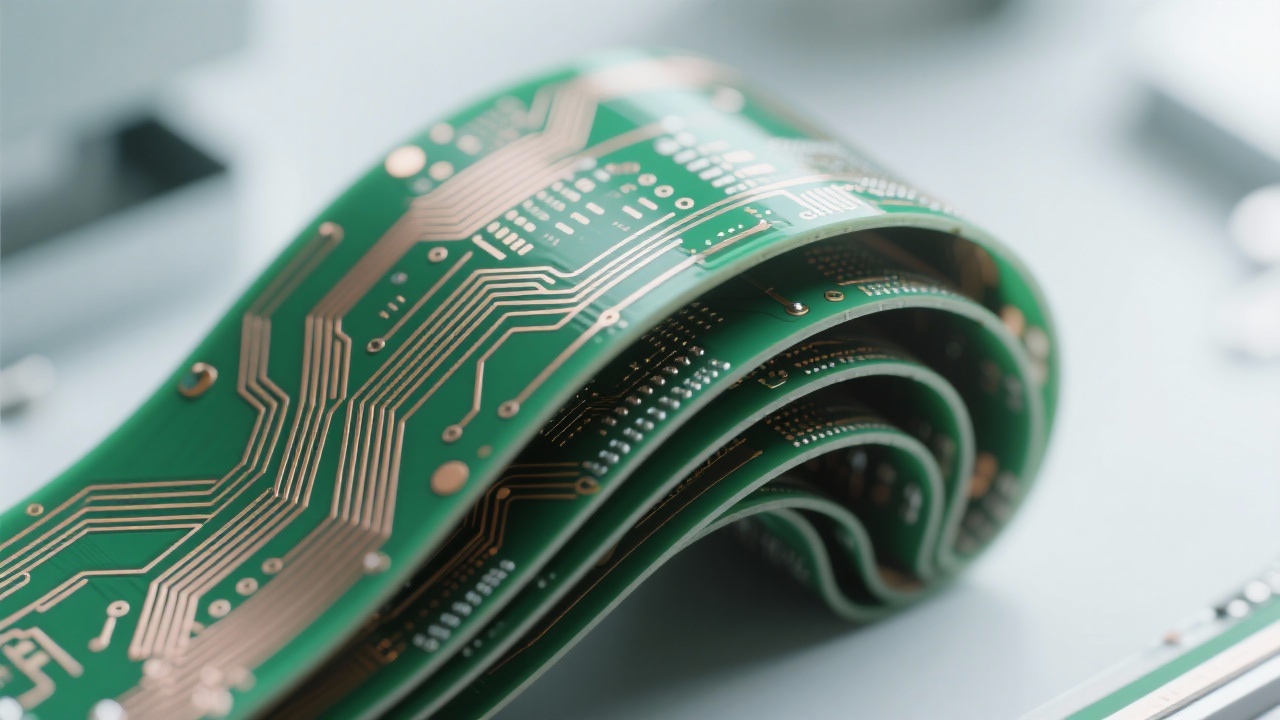

Another problem is the stress concentration during bending. Flexible circuit boards often need to be bent during use, and stress concentration can lead to cracks and reduced reliability. Our article provides solutions to enhance the reliability of FPCs under bending conditions, such as using special materials and structural designs.

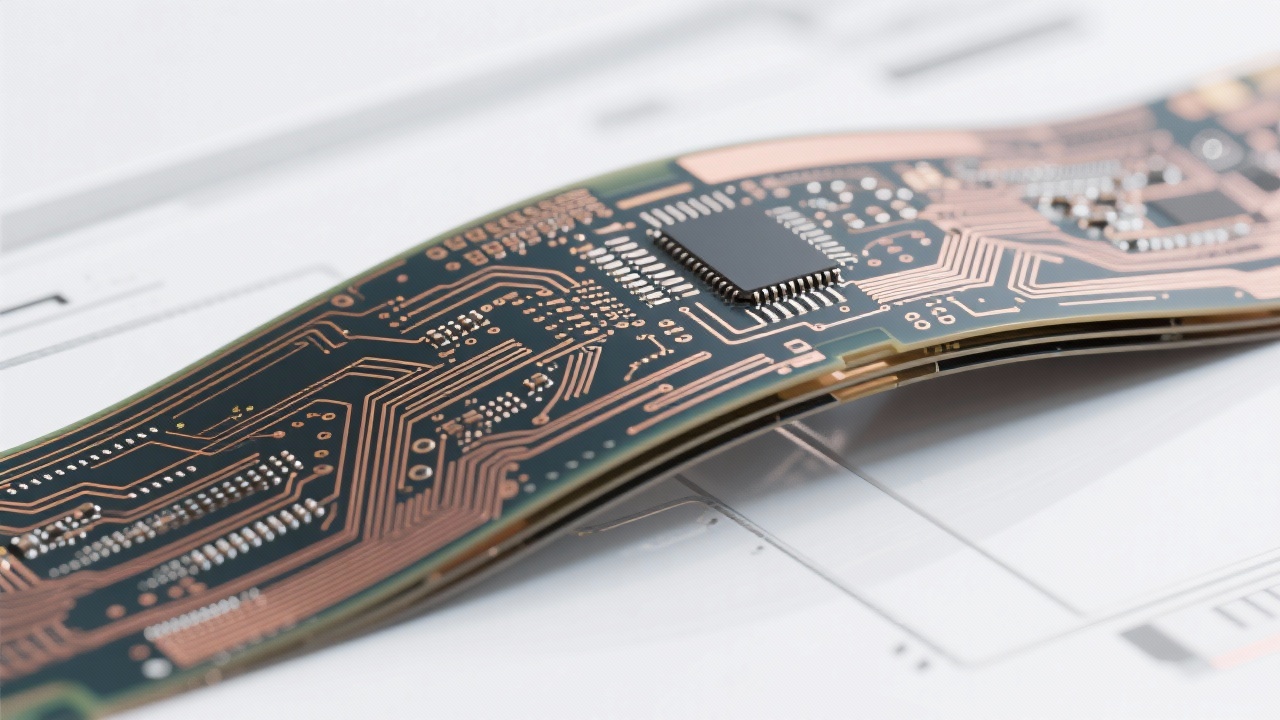

On the manufacturing side, precision processing technologies are essential for mass - producing complex high - density designs. The minimum hole diameter is 0.2mm, which requires high - precision drilling and other processing techniques. These advanced manufacturing technologies support the implementation of complex high - density designs, ensuring that the designed products can be mass - produced with high quality.

This article combines industry standards and the latest technologies, integrating practical cases and product recommendations. It aims to provide engineers with a comprehensive guide from design principles to production processes, helping them fully master the technical framework of high - density flexible PCB design and promote the improvement of product performance and reliability.

If you are an engineer or a professional in the field of flexible circuit boards, and you want to learn more about high - density FPC design and manufacturing, click here to explore our in - depth solutions and take your product to the next level!

-4.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)