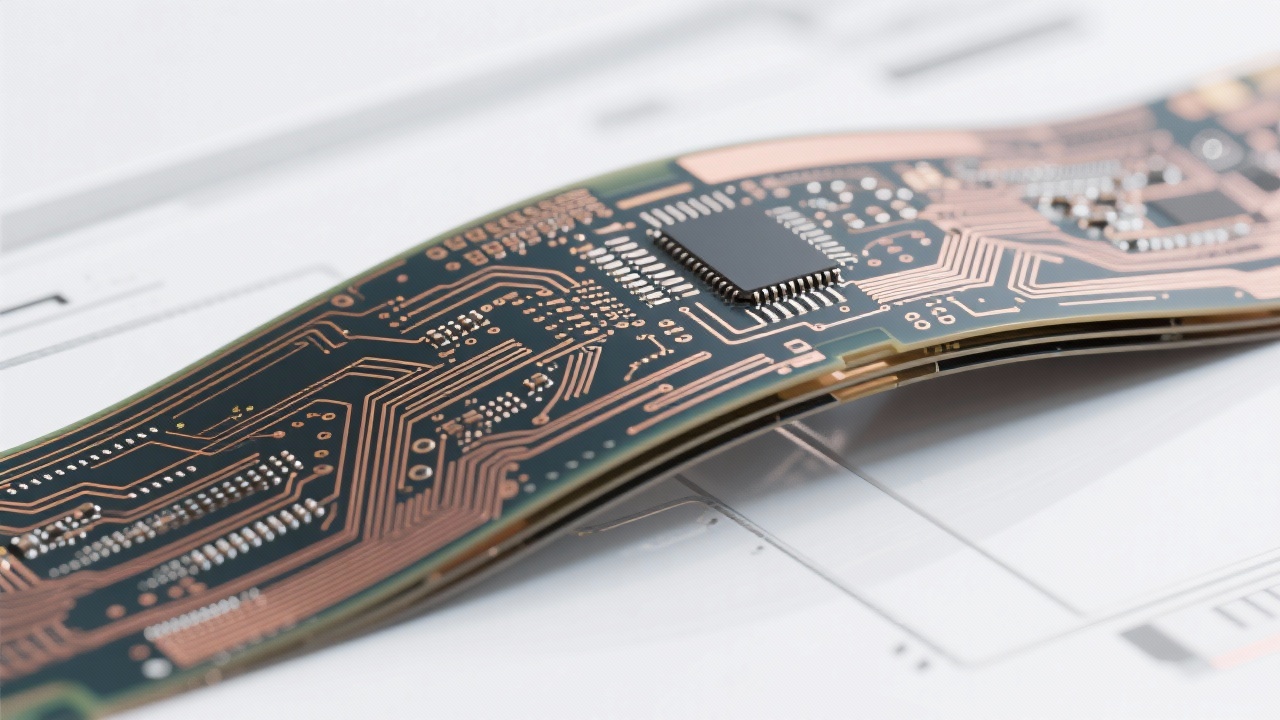

In today’s compact electronics landscape—from wearables to medical devices—designers face relentless pressure to pack more functionality into smaller spaces. This challenge is especially acute in multi-layer flexible printed circuit boards (FPCs), where high-density routing demands precision not only in layout but also in via placement, micro-hole drilling, and signal integrity management.

As consumer electronics shrink and medical devices become increasingly miniaturized, the industry standard for trace width and spacing has dropped to as low as 0.1mm—with via diameters now routinely under 0.2mm. According to IPC-2221 standards, maintaining a minimum via-to-trace clearance of at least 0.15mm ensures reliable electrical performance during bending cycles. Yet many manufacturers still struggle with stress concentration at fold points—a leading cause of early failure in flexible assemblies.

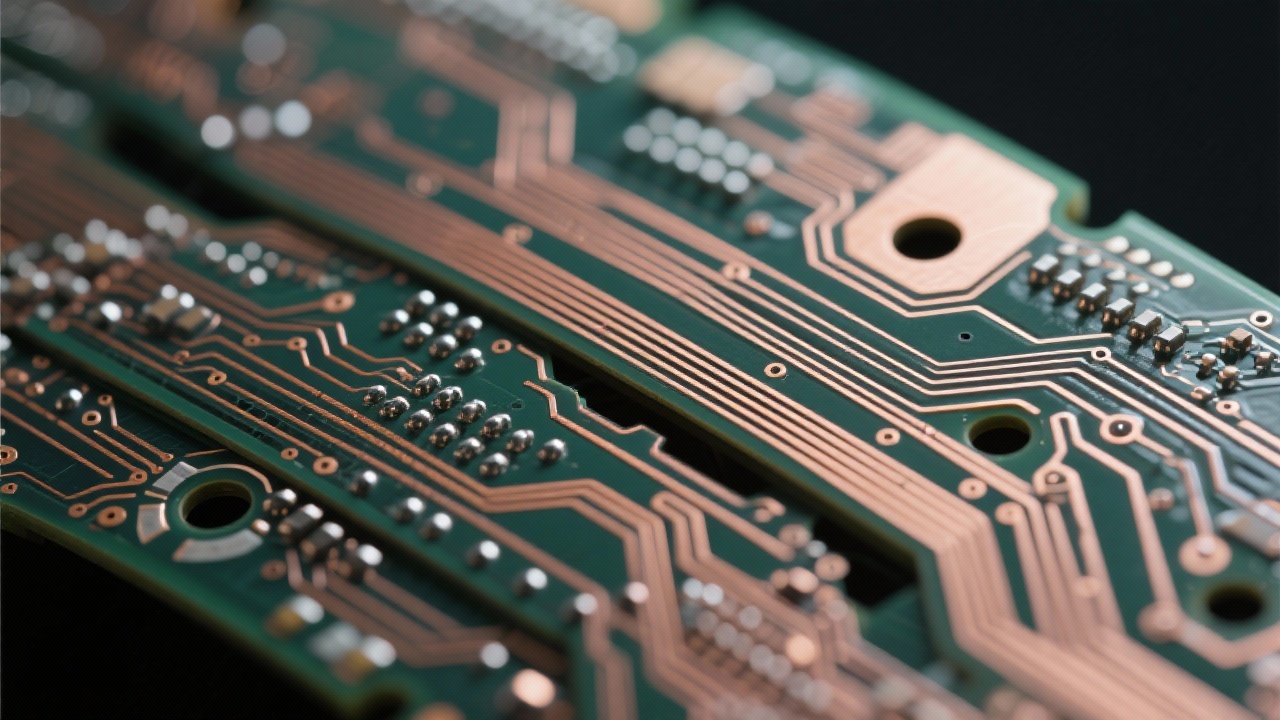

With increasing data rates in IoT and wearable tech, electromagnetic compatibility (EMC) isn’t optional—it’s critical. A well-designed via array can reduce crosstalk by up to 40% when properly spaced and grounded. For example, using via fences around sensitive analog lines (per IEEE 299 guidelines) significantly improves noise immunity in medical-grade FPCs used in pacemakers or EEG sensors.

Our engineering team at [Your Company Name] leverages simulation tools like Ansys SIwave and Altium Designer to model real-world scenarios before prototyping. In one recent case study involving a client developing a flexible endoscope, we reduced EMI emissions by 37% through optimized via stacking and shielding techniques—without sacrificing board flexibility or yield.

Beyond design rules, reliability hinges on material choice and manufacturing consistency. Polyimide substrates with controlled dielectric constants (typically 3.4–3.6) perform better than standard FR-4 in dynamic environments. Additionally, our proprietary micro-via plating process achieves >98% fill rate—even for holes as small as 0.18mm—ensuring robust mechanical and electrical connections after repeated flexing.

Whether you’re designing a smartwatch module or an implantable sensor, understanding how vias behave under strain is essential. We’ve developed a fatigue life prediction model based on over 500 test samples from actual field deployments, allowing us to recommend optimal via density and pad sizes tailored to your product’s expected lifespan.

Explore our full suite of multi-layer flexible PCB solutions—engineered for performance, reliability, and scalability across industries.

From initial concept to volume production, our team supports engineers who demand precision—not just compliance. Whether it's optimizing via patterns for minimal signal loss or ensuring micro-via reliability in extreme conditions, we bring both technical depth and practical experience to every project.

-4.png?x-oss-process=image/resize,h_800,m_lfit/format,webp)