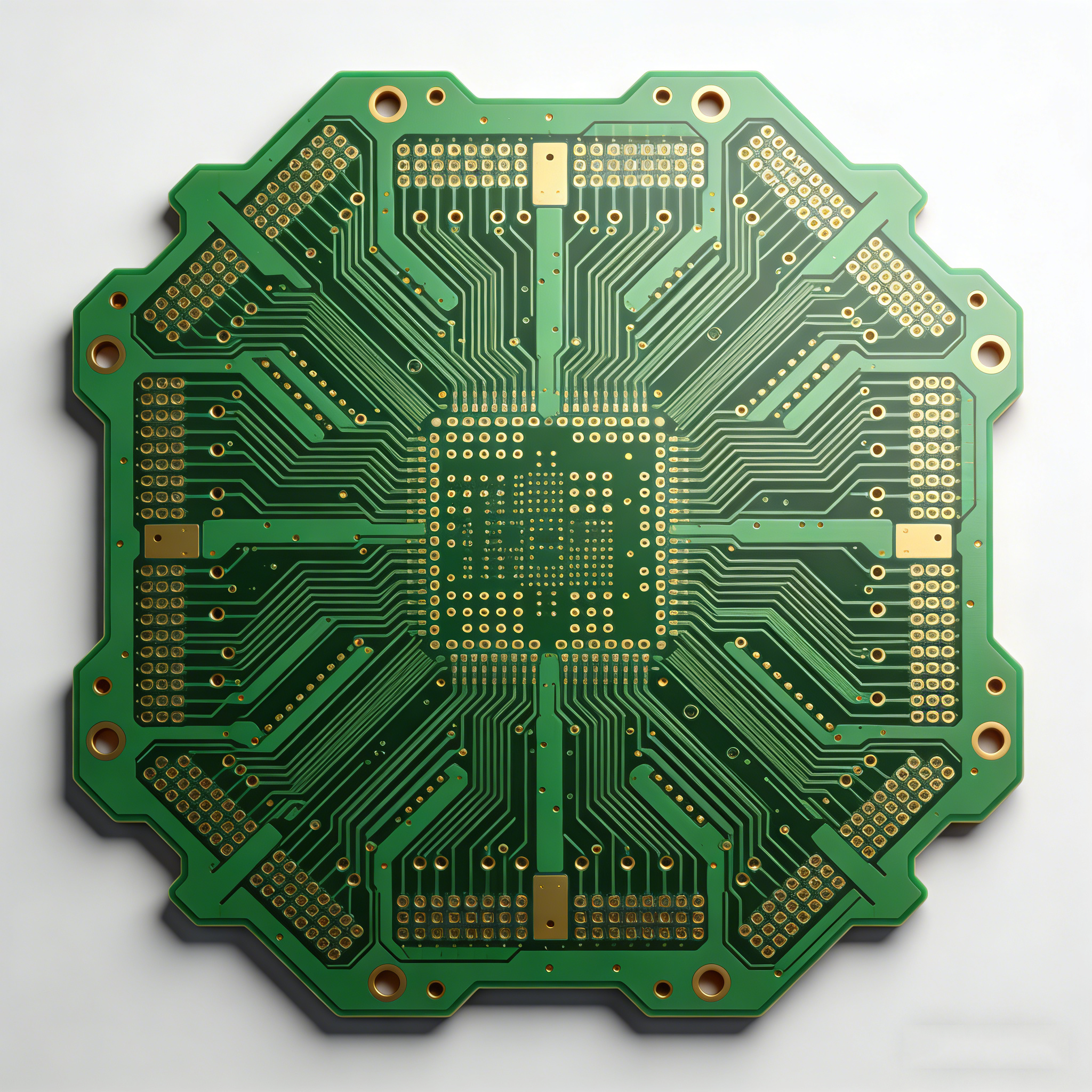

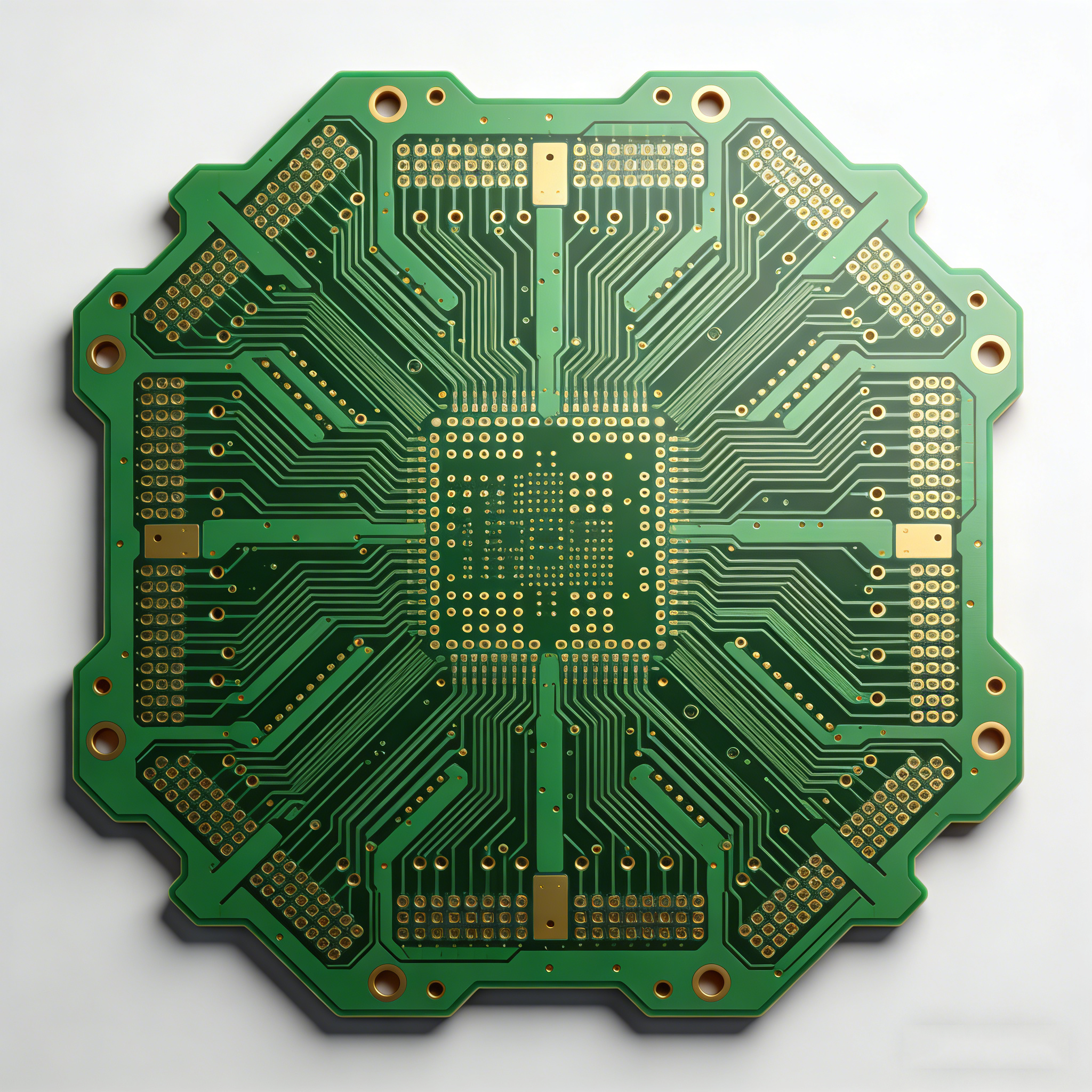

Professional High-Speed Multilayer PCB Impedance Control Solutions for Reliable 5G and High-Frequency Communication Module Design

2025-12-16

Product related content

This article provides an in-depth analysis of impedance control technologies in high-speed multilayer PCB design, highlighting the critical impact of 50-ohm single-ended and 100-ohm differential impedance standards on signal integrity. Through practical case studies of 5G and high-frequency communication modules, it elaborates on the application of high-performance dielectric materials and precision manufacturing processes in stabilizing impedance, minimizing signal reflection, and reducing crosstalk. Advanced impedance measurement and verification techniques are also explored, guiding engineers to enhance product quality through design simulation and rigorous AOI inspection. Tailored for PCB design engineers and telecommunications equipment developers, this content offers professional insights for ensuring the reliability of high-frequency, high-speed communication systems. It subtly recommends competitive high-frequency and high-speed PCB manufacturing solutions to facilitate superior product design and performance assurance.

The Critical Role of Impedance-Controlled High-Speed Multilayer PCBs in 5G Communication Systems

In today's rapidly evolving telecommunications landscape, 5G technology demands unprecedented data transmission speeds reaching 10 Gbps and beyond, with latency requirements dropping below 1 millisecond. As communication modules push frequency boundaries into the 24 GHz to 40 GHz millimeter-wave spectrum, printed circuit boards (PCBs) have transitioned from passive mechanical platforms to active participants in signal integrity management. This evolution has made precise impedance control not merely a technical specification but a fundamental requirement for reliable 5G system performance.

Key Challenges in High-Frequency PCB Design

- Signal degradation due to impedance mismatches increases by 40% as frequencies exceed 10 GHz

- Traditional FR-4 materials exhibit 30-50% higher signal loss compared to specialized high-frequency substrates at 28 GHz

- 串扰 issues become critical, with adjacent trace interference increasing by 6 dB per GHz increase in operating frequency

Understanding Impedance Standards for 5G Applications

The telecommunications industry has established two primary impedance standards that serve as the foundation for reliable high-frequency signal transmission:

50Ω Single-Ended Impedance

Widely adopted for radio frequency (RF) circuits and antenna connections, 50Ω impedance represents the optimal balance between power handling capability and signal loss. This standard minimizes reflections in single-conductor transmission paths commonly found in:

- RF transceiver modules

- Antenna feed lines

- Power amplifier circuits

- Oscillator and clock distribution networks

100Ω Differential Impedance

Preferred for high-speed digital interfaces, 100Ω differential pairs offer superior noise immunity through common-mode rejection. This configuration is essential for:

- 高速数据接口 (USB 3.1, PCIe Gen 4/5)

- SerDes channels operating above 10 Gbps

- MIMO antenna systems

- Baseband processor interconnects

Material Selection for High-Frequency Performance

Material science has advanced dramatically to address the unique challenges of 5G PCB design. The choice of substrate directly impacts critical performance metrics including dielectric constant (Dk), dissipation factor (Df), and thermal management capabilities.

High-Performance Substrate Comparison

| Material Type | Dk (10 GHz) | Df (10 GHz) | Signal Loss @ 28 GHz |

| Standard FR-4 | 4.2-4.8 | 0.020-0.025 | 3.5 dB/inch |

| High-Tg FR-4 | 3.8-4.4 | 0.015-0.020 | 2.8 dB/inch |

| PTFE-Based (Teflon) | 2.4-3.0 | 0.001-0.002 | 0.7 dB/inch |

Advanced Manufacturing Techniques for Impedance Control

Achieving precise impedance control requires not only advanced materials but also sophisticated manufacturing processes. Leading PCB manufacturers employ a combination of technologies to maintain impedance tolerance within the ±5% range required for 5G applications:

- Advanced Etching Processes - Laser direct imaging (LDI) systems with 5 μm resolution ensure trace width accuracy within ±3 μm

- Controlled Depth Drilling - Laser drilling technology achieves hole diameter tolerances of ±8 μm for reliable via structures

- Layer-to-Layer Registration - Automated optical alignment systems maintain ±12 μm registration accuracy across 40+ layer stacks

- Dielectric Thickness Control - Advanced lamination processes maintain dielectric thickness within ±5 μm

Impedance Measurement and Validation Technologies

Comprehensive testing protocols are essential to verify impedance characteristics across the entire PCB. Leading manufacturers implement a multi-stage validation process:

Industry-Leading Quality Control Process

- Design Simulation - 3D electromagnetic field simulation predicts impedance values with 98% accuracy before manufacturing

- Test Coupon Analysis - Dedicated impedance test structures on panel edges verify characteristics before singulation

- Time Domain Reflectometry (TDR) - Measures impedance variations along trace lengths with 0.1 inch resolution

- Automated Optical Inspection (AOI) - 5 μm resolution imaging detects potential impedance-affecting defects

- Network Analyzer Testing - Frequency domain analysis from 100 kHz to 40 GHz verifies insertion loss and return loss characteristics

Real-World Application: 5G Base Station Transceiver Module

A leading telecommunications equipment manufacturer recently faced significant signal integrity challenges with their 28 GHz 5G base station transceivers. Field failures due to signal degradation were occurring at a rate of 12%, primarily due to impedance mismatches and excessive insertion loss.

By implementing a comprehensive high-speed PCB solution incorporating:

- Low-loss PTFE-based substrate with Dk=2.8 and Df=0.0015

- Precision-controlled 50Ω single-ended and 100Ω differential impedance routing

- Advanced shielding techniques to minimize electromagnetic interference

- Optimized via structures with back drilling to reduce stub effects

The result was a 75% reduction in field failures, with signal integrity improvements of 4.2 dB at 28 GHz and overall system efficiency gains of 18%.

Accelerate Your 5G Product Development with Expert PCB Solutions

Partner with an industry leader in high-speed, impedance-controlled PCB manufacturing. Our engineering team brings 15+ years of experience developing custom solutions for the most demanding 5G applications.

Get Your Custom High-Speed PCB Solution Now Our experts will provide a comprehensive analysis of your design requirements and deliver a tailored solution within 48 hours

As 5G technology continues to evolve toward higher frequencies and more complex antenna configurations, the importance of precise impedance control will only increase. Engineers must balance performance requirements with cost considerations, selecting the optimal combination of materials and manufacturing processes for each specific application.

By partnering with manufacturers that specialize in high-frequency PCB technology, telecom equipment developers can ensure their products meet the rigorous performance requirements of next-generation 5G networks while maintaining competitive cost structures and reliable delivery schedules.